North Kivu, Democratic Republic of Congo

Located on the majestic shores of Lake Kivu, several key environmental factors align: mineral-rich black soil, high altitudes, and favorable weather patterns.

But exceptional coffee is far from being the result of environmental conditions alone; it is also the result of careful cultivation. The co-op has invested in two particularly key additional areas: processing and staff capacity building.

Processing

SOPACDI uses a variety of proven sorting techniques, with each step further selecting for the best beans within the harvest. The results of their systematic, consistent processing are undeniable, particularly in the clarity of the flavor in the end cup. For details on their processing methods – including what is known as the Rwandan style of fermentation – see below.

Capacity Development

Inspired by the results of her work with cuppers at source in several other partner co-ops, our Quality Control manager Beth Ann traveled to SOPACDI to help interview and hire two cuppers. Like many of the projects she undertakes, this assignment didn’t have much precedent and she and the co-op staff got creative. For details on their creative process and the results, see below. Look for more news about the cuppers in the coming months when they come to Equal Exchange for a two week cupping and roasting seminar.

Details on the SOPACDI processing method

Many of SOPACDI’s farmers process their coffee through a centralized wet processing mill. At the mill, farmers are paid based on the color and consistency of the coffee cherries which is a significant determinant in quality. Cherries are then deposited into a large flotation tank. Those that sink are of good quality; those that float are removed. The cherries are then put through a mechanized depulper which removes the skin and flesh from the seeds inside.

The Congolese use what is known as Rwandan style fermentation, a wild fermentation where nothing is added.

- Step 1: Dry fermentation – in a concrete tank for 24 hours. This breaks down the mucilage that remains on the coffee seeds.

- Step 2: Wet fermentation – with water in a second tank for 12 hours. Coffee is then lightly washed, graded and separated.

- Step 3: Final wet fermentation – graded coffee is then fermented in a third tank for 12 more hours.

Once fermentation is complete, coffee is fully washed and then dried on raised African drying beds for 4-8 days, depending on the weather.

Identifying Cuppers at SOPACDI

By Beth Ann Caspersen

As a sensory professional, I have had the unique opportunity to work with coffee cuppers all over the world. I put this knowledge to work in D.R. Congo last Fall to help SOPACDI find a coffee roaster and cupper for their growing cooperative. It was an exciting process and experience for me and the people we interviewed for the position.

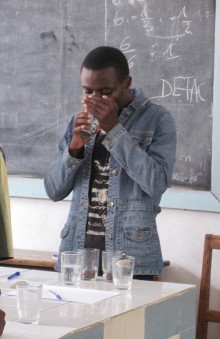

The cooperative selected 16 candidates from different coffee-growing communities, both male and female, between the ages of 18 and 25 years old. In order to be a cupper and quality control professional, it is necessary to read, write and communicate both within and outside the cooperative, and therefore it was required that each candidate have a high school education to participate. Our workshop took place in the chemistry lab of a Christian school which had the most reliable source of electricity available and could entertain our large group.

Our first day focused on the basics of flavor through tasting and smelling exercises, cupping as a process and identification of basic flavors. This activity was very foreign for many of the students, especially since they don’t drink coffee on a daily basis. Many of them enjoy Chai – a milky tea consumed throughout East Africa – but had little experience drinking coffee without sugar. In addition to working through the basics of coffee, I wanted to demonstrate the power of tasting through everyday life. All of the flavors found in Congolese cuisine contain basic flavors that were familiar to the candidates: the sweetness of boiled bananas or fresh mangos, the potato-like texture of Yuca or the leguminous and grassy flavors found in beans. I also wanted to introduce candidates to a broader way of thinking about flavor through cross product identification and training. We tasted milk chocolate, dark chocolate and a series of dried fruits like apricots and cherries, all to introduce them to flavors that we find on the cupping table. These delicious foods helped to open their eyes.

I was looking for the people that could translate the aromatics and these new basic flavor experiences into coffee. Could they identify any of these flavors? Were they able to describe the weight and texture? Were they able to articulate the bright and zesty sensation on their tongue? The selection process culminated in a series of exams to test their aroma memory recall, basic flavors and flavor identification in both defective and amazing coffee. I was also seeking people who had great attention to detail, a willingness to experiment and try new things, the ability to take direction and a great attitude. By the end of the seminar I had identified two fantastic people for the job!