Coffee Quality Manager Beth Ann Caspersen recently traveled to the Democratic Republic of the Congo to judge the country's first-ever coffee cupping competition. This is the fourth blog post in the series about the visit. Read part one here.

Coffee provides an important economic base to many people living in the Eastern Democratic Republic of the Congo (DRC) and the industry is growing in the country. Equal Exchange has bought coffee from the DRC since 2011, and over the years we have seen the coffee go from good to amazing. So, when I was approached to be the head judge for the first-ever coffee cupping in DRC, it was a logical yes. Over the last couple of blog posts, I have shared a variety of my experiences leading up to the competition, and the next few posts will focus on the operational challenges we encountered, how that work was supported, and why Saveur du Kivu was a historic moment for the DRC and for me. It definitely took a team of dedicated people to make it all happen.

There is a reason that I took the job as head judge; I have done competitions before, I have led trainings, taught classes, been to many different coffee cupping labs all over the world - both advanced and basic. I knew that the lab and circumstances under which I would need to operate would not be ideal. I had been in the SOPACDI lab in Minova last November struggling with a generator and roasting by flashlight at night, so in a sense, I knew what I was getting into. But I don’t think I quite understood the extreme nature of this project.

I didn’t know that all of the preparation and luxuries like running water, electricity, a seasoned coffee roaster, cuppers, etc. would not be ready upon my arrival, and I would have four days to prepare for and execute a high caliber coffee competition in which 10 international buyers would be coming to participate.

Day 1

Things move more slowly in the DRC. The Western ideas of rushing around and counting the minutes seemed to have floated out of the room with all of the instructions I had provided in advance which was not one of culture, but one of infrastructure. We arrived on the ferry that had just taken us across the crystal blue waters of Lake Kivu at approximately 10 a.m. on that Friday morning and went straight to the lab. Words can’t really describe how I felt; I could see workmen rushing around a large white building and as I entered, I was greeted by wires jutting out of the ceiling, dirt and dust covering the floors in each of the empty rooms, and paint fumes that filled my lungs. I felt my heart go up in my throat, which for me can sometimes mean the tears are coming, but this time it was complete disbelief.

All I could think was, “Oh my goodness, how are we going to get this preparation done by Tuesday? It was Friday morning and there was no running water, no electricity, the generators had not arrived (the back up plan) and suddenly I looked around and asked, “Where is everything else?” The coffee cups, water, kettles to boil the water…And I still needed to see the coffee roaster. But there it was - a small double barrel Joper, pleasantly wrapped in plastic and sitting quietly in a wood crate in the corner of the room. We took a quick inventory of the materials we had and what was still needed, and it was then that I did what I do best: I started to organize, problem solve and orchestrate the group.

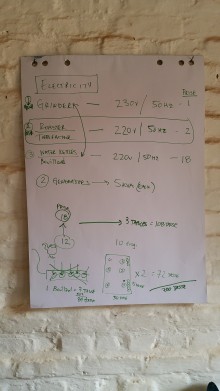

First I got the entire team together: contractors, electricians, representatives from the Organizacion Nacional du Café (ONC) and Eastern Congo Initiative (ECI) - everyone gathered in one room to discuss priorities and execution. This was not a time to point fingers or get mad; we had to get to work. I started to imagine the primary pieces of equipment that needed to be installed. We opened boxes and looked at electrical specifications. Lucky for me, I had an amazing translator, some butcher paper, a marker and an assertive voice. Then I led the group through each piece of equipment, asking for input and creating a set of marching orders that were to be our guide. All painting was to stop; water, electricity and the acquisition of two generators were the top priority. Then I looked at the brand new double barrel Joper coffee roaster that was still sitting in a box and knew I had to start roasting as soon as possible.

Stay tuned for the day two recap.